t is an advanced manufacturing process that uses computer-controlled machines to shape and cut metal materials. Utilizing computer numerical control (CNC) techn

LEARN MORE →

Xiamen Wiesel technology mainly provides metal 3D printing,plastic CNC,sheet metal fabrication,metal CNC,stamping mold,plastic mold,plsatic 3D printing,plastic

LEARN MORE →

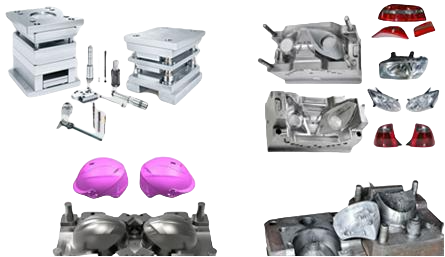

Xiamen Wiesel technology Co., Ltd focuses on the research and development of customized plastic molds, die-casting molds, and rapid prototyping. We have been co

LEARN MORE →

Xiamen Wiesel technology Co., Ltd mainly provides stamping mold,metal 3D printing,plastic rapid prototype,PMMA/PC_CNC,sheet metal fabrication,metal CNC,plastic injection moulding,vacuum casting,plastic CNC,autocad mold design, etc., which can be used in Transportation ,Robotics ,Textile ,Consumer goods ,Home appliances ,Industrial manufacturing,Oil and gas ,Entertainment and other industries. The machining process begins by using CAD software to create a 3D model of the desired part. The model is then imported into CAM software, which generates tool paths and instructions for the CNC machine tool. Once the design and specifications are finalized, the metal pieces are mounted on the CNC machine and the cutting tools begin running.

LEARN MORE →

They are equipped with specialized tools such as Tungsten carbide tool,Threading tool,Diamond cutting tool,Thread mill,Adjustable woodruff cutter,Facing tool,Countersink,Parting tool and grinders, which are programmed to rotate, rotate and move according to specifications set by the design software. This allows for precise shaping and cutting of different types of metals, including Cast iron,Bronze,Silicon,Carbon steel,Phosphorus bronze,Lead,Manganese,Nitinol,Brass alloy.

LEARN MORE →

Xiamen Wiesel technology Co., Ltd mainly provides metal CNC,sheet metal fabrication,plastic injection moulding,plastic mold,die casting mlding,PMMA/PC_CNC,metal 3D printing,vacuum casting,stamping mold,asm al-si alloys casts by die casting, etc., which can be used in Solar energy ,Defense ,Metalworking ,Education ,Food and beverage ,Electronics ,Aerospace,Medical and other industries. The machining process begins by using CAD software to create a 3D model of the desired part. The model is then imported into CAM software, which generates tool paths and instructions for the CNC machine tool. Once the design and specifications are finalized, the metal pieces are mounted on the CNC machine and the cutting tools begin running.

LEARN MORE →

It is controlled by a computer program that directs the machine's movement, speed and cutting depth to make precise and complex cuts in metal materials. Metal materials used in CNC machining range from Nickel,Titanium,Bronze,Carbon steel,Vanadium,Brass alloy,Bronze alloy,Zinc,Tungsten,Gold and other alloys. CNC machining is commonly used in various industries, including Food and beverage ,Defense ,Education ,Home appliances ,Automotive,Solar energy ,Transportation ,Electronics ,Construction and electronics, to produce parts with high precision and tight tolerances. The process produces parts with a smooth surface finish and tight dimensional tolerances, reducing the need for additional finishing processes. Metal CNC machining is a reliable, efficient method for producing high-quality metal parts for a variety of applications.

LEARN MORE →

Xiamen Wiesel technology Co., Ltd mainly provides plastic injection moulding,sheet metal fabrication,gear CNC for plastic/metal,PMMA/PC_CNC,plastic CNC,vacuum casting,stamping mold,die casting mlding,plastic mold,arbor press injection mold, etc., which can be used in Telecommunications ,Aerospace,Musical instruments ,Furniture ,Food and beverage ,Entertainment ,Defense and other industries. It is equipped with advanced software that allows for precise control of cutting tools, resulting in consistent and uniform production. This method provides excellent repeatability, ensuring every part is identical and meets the required specifications.

LEARN MORE →

It is a computer numerical control (CNC) machining process that uses rotating tools to remove material from a Magnesium aluminum alloy,Vanadium,Molybdenum,Hastelloy,Stainless steel,Silver,Iron,Manganese workpiece. The process is controlled by a computer program that uses precise measurements and instructions to achieve a high level of accuracy and repeatability.

LEARN MORE →

It is versatile and can be used to create a variety of parts from simple to complex designs using a variety of metals including Hastelloy,Silicon,Platinum,Brass alloy,Titanium,Manganese,Zinc alloy,Inconel. The precision and consistency of these machines allows for tight tolerances and surface finishes to produce high-quality products and minimize waste.

LEARN MORE →