Reasonable Mold Design good for reducing Injection Molding Cycles and Mold Cost

Learn more

Injection molding is a complex design, Reasonablemold design is good for reducing injection Molding Cycles and increasing Moldlife.Mold Design include Runner system, Cooling system, Ejection System,Guidance System,Exhaust System.

Most effective and Easy way for us

Free build 3D file for customer

Less Cost For 3D build

Different thermoset materials have the different shrinkage. When mold design, how to choose the shrinkage of material is very important .Some Shrinkage of material is in below list:

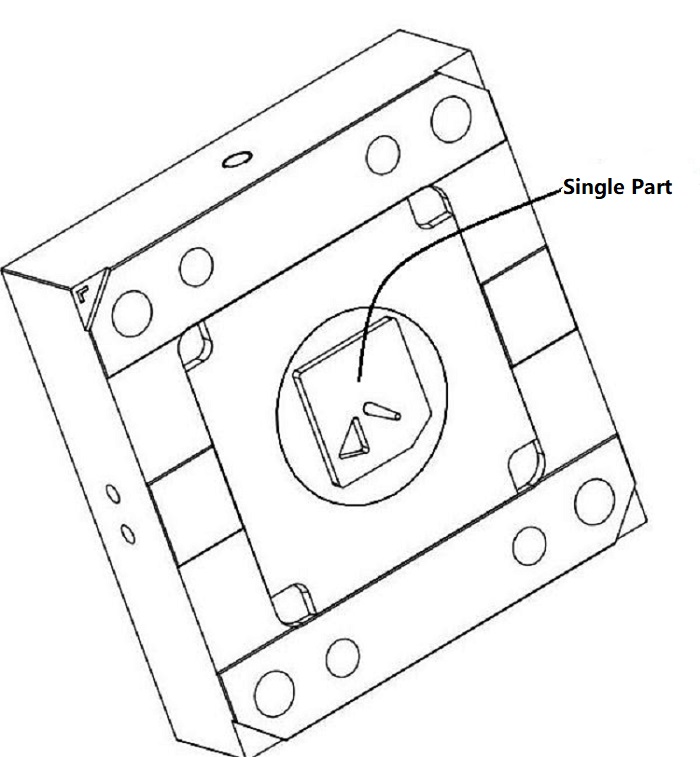

Only one cavity for part, it is good for small order

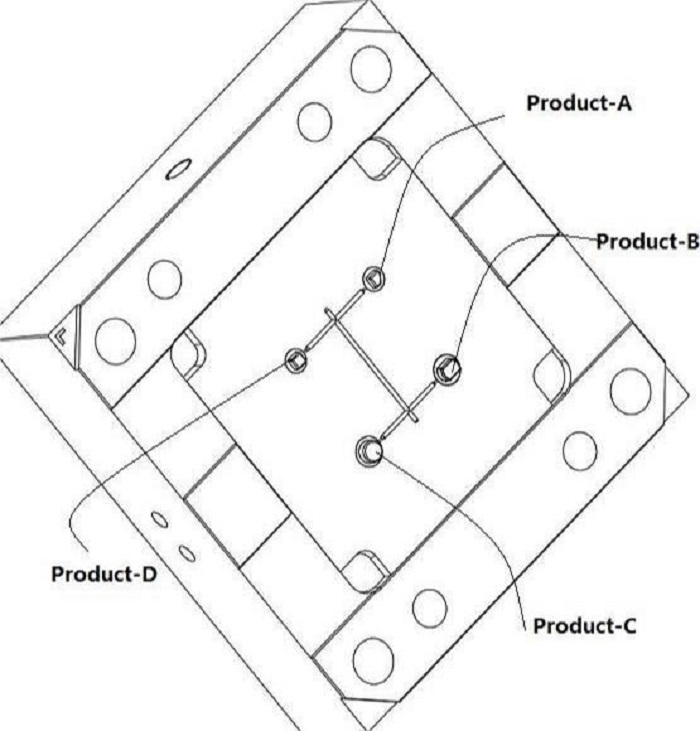

Many parts are in one mold, it is good for many similar parts of small order

the mold is good for different color and material in part.

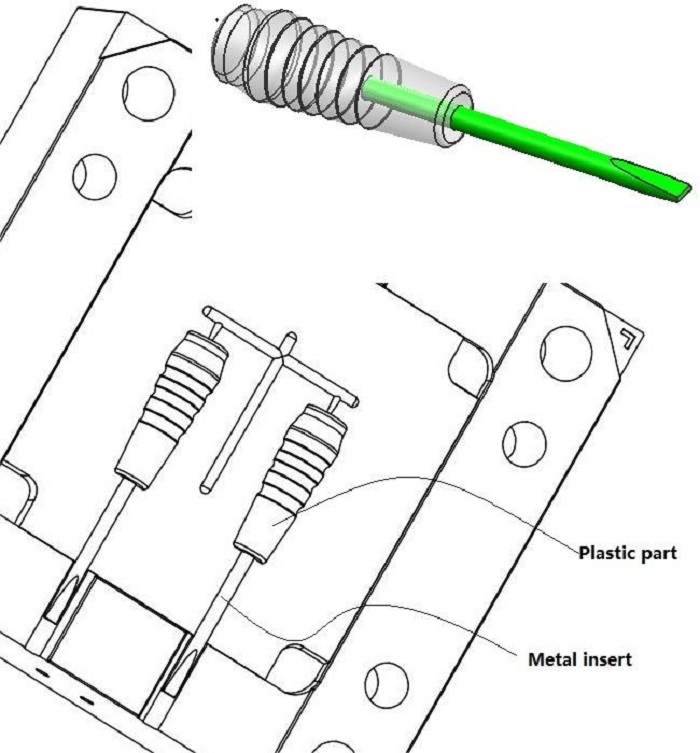

Mold is for plastic with metal, normally, the material of metal is steel, brass,etc.

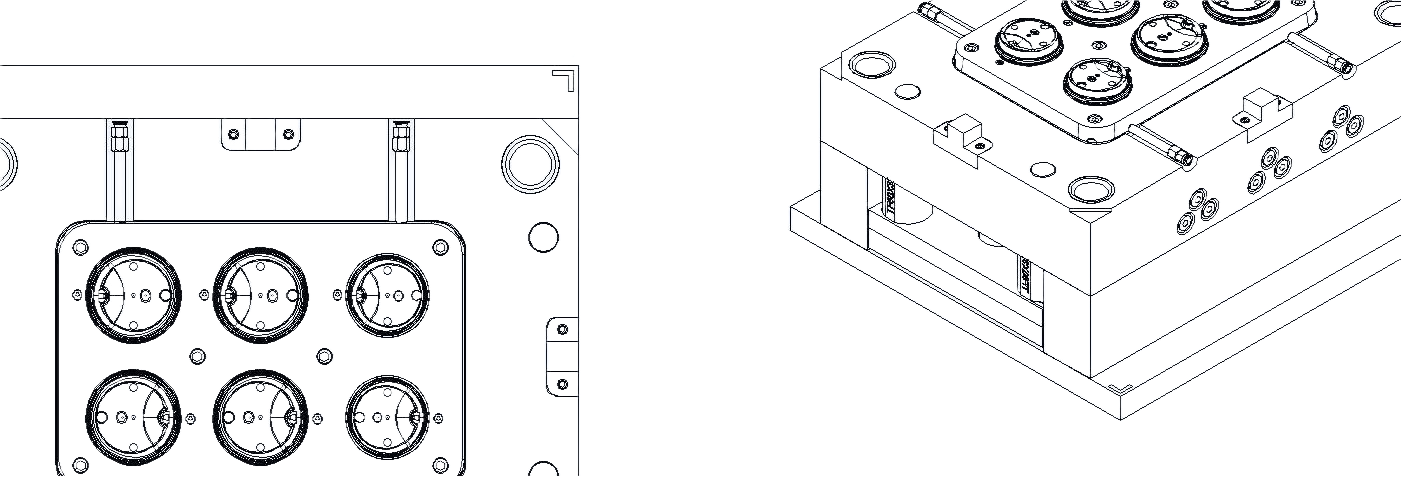

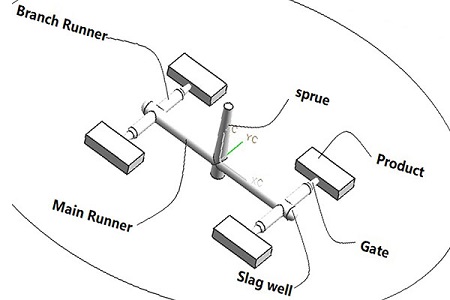

Running System

The Flow Running before plastic enters the mold from the nozzle, including Sprue,Main runner, Branch runner,Slag Well,Gate.

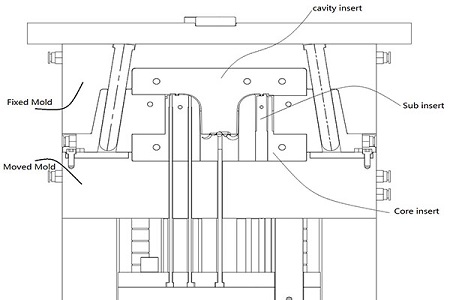

Form System:

The system refers to various combinations of parts that form the shape of a product, including moved mold (Core side) and fixed mold (Cavity side). The moved mold forms the inner surface of the product, the fixed forms the outer surface shape of the product.According to process and manufacturing requirements, Sometimes, the core and cavity inserts are composed of severial assembly parts, Sometimes inserts that made into a whole that are easily damaged and difficlut to machine

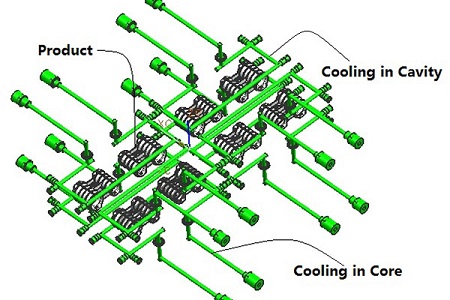

Cooling System:

Cooling system is required to meet the temperature requirements of the injection process for the mold, and it is necessary to have a cooling system to adjust the temperature of the mold. The common method of mold cooling is to set up a cooling water channel inside the mold, which uses the circulating cooling water to carry away the heat of the mold; The heating of the mold can not only utilize cooling water to pass through hot water or oil, but also install electric heating elements inside and around the mold

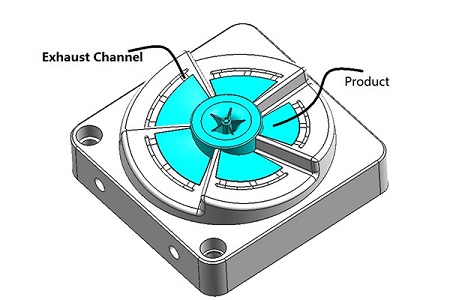

Exhaust System:

Exhaust system is set up to exhaust the air in the injection molding process and the gas generated by the melting of plastic into the mold. When the exhaust in not smooth, the surface of the product will form air marks,charring and other defects. The exhaust system of plastic mold is usually a slot shaped air outlet that set up in the mold to exhaust the air in the original mold and the gas brought in by the molten material.

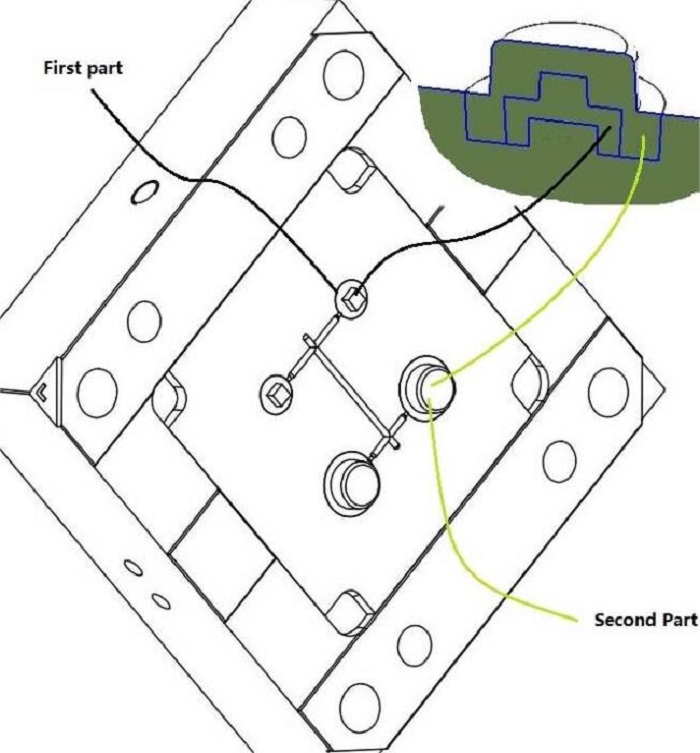

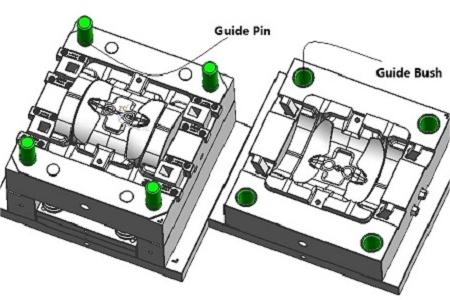

Guidance System:

Guidance System is established to ensure accurate alignment between the moved and fixed half during mold closing,four sets of guide pin and guide bush are usually used to form the guiding components. Sometimes, it is necessary to set up mutually matched inner and outer conical surfaces on the moved and fixed half to assist in position.

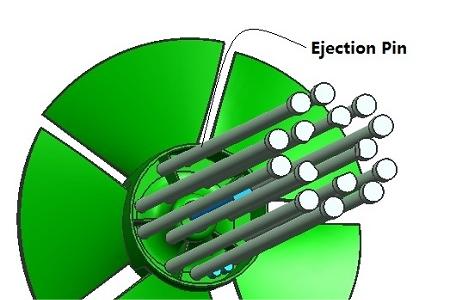

Ejection System:

After the product is formed and cooled in the mold, when mold is opened, the ejection mechanism (ejection pin) is pushed by the ejector pin of the injection machine, then the product and runner system is pushed from the core side, in order to proceed with the next molding cycle.

We have experienced project managers and multilingual salesman for your projects. They can send you the support from Mold design to Production.

Wiesel has many engineers who have more than 10 years experience in Mold Design and Manufacturing. We also use the speciality software for Design and Manufacturing.( CAD/CAE/CAM)

Wiesel can support the different design for different quantity and moldlife. We will choose a best way to meet the customer need.

Wiesel offer much additional service to complete the projects:Scan sample to build 3D drawing,Optimize structure of product.

Provide Comprehensive Product Technology Solutions

Need custom plastic mold design? Please contact with us