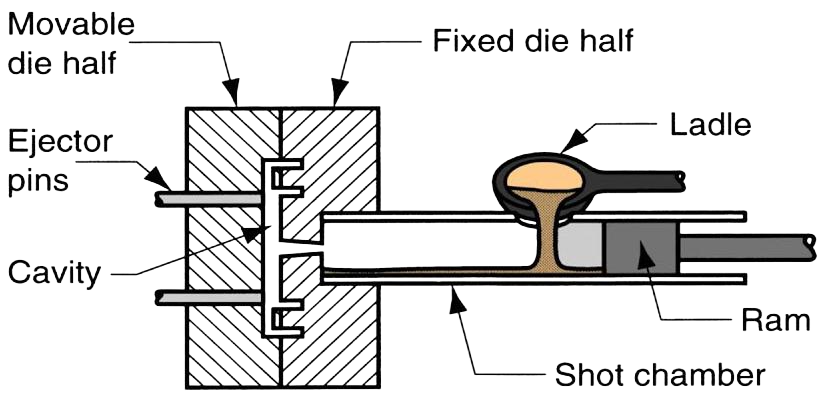

Die Cast Zinc Alloy Mold is also commonly known as Dies. These molds are used for the mass-production of zinc alloy parts. Mold making used to be a difficult task before. Thanks to the CNC Machining technology mold making is now faster and more efficient than ever.

Zinc-alloy Die casting Mould requires a material that has higher strength and melting temperature than Zinc. Otherwise, the die will be damaged during the casting process. Usually, steel molds are used for Zinc die casting.

High-quality steel is quite costly and hard to machine. So, the die tooling cost is relatively high. Even though the high tooling cost,Zinc-alloy die casting toolings provides the best economy and quality for large volume production.

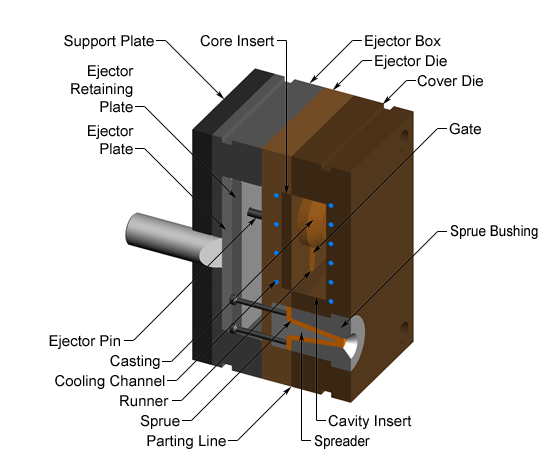

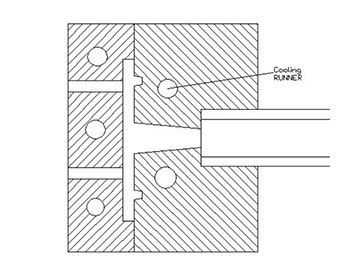

A Die Cast Mold consists of multiple parts with each serving a specific purpose. The main components in a die casting mold are listed below.

| Type | Hardness(HB) | Tensile Strength(MPa) | Yield Strength(MPa) | Impact Strength (J) | Shear Strength(MPa) | Elongation Rato(%in 50mm) |

| Zamak3 | 82 | 283 | 221 | 58 | 214 | 10 |

| Zamak5 | 91 | 328 | 228 | 65 | 262 | 7 |

| Zamak7 | 80 | 283 | 221 | 58 | 214 | 13 |

| Zamak2 | 100 | 359 | 283 | 47 | 317 | 7 |

| ZA-8 | 103 | 374 | 290 | 42 | 275 | 10 |

Provide Comprehensive Product Technology Solutions