Why Are Zinc Alloy Molds Ideal for Precision Manufacturing?

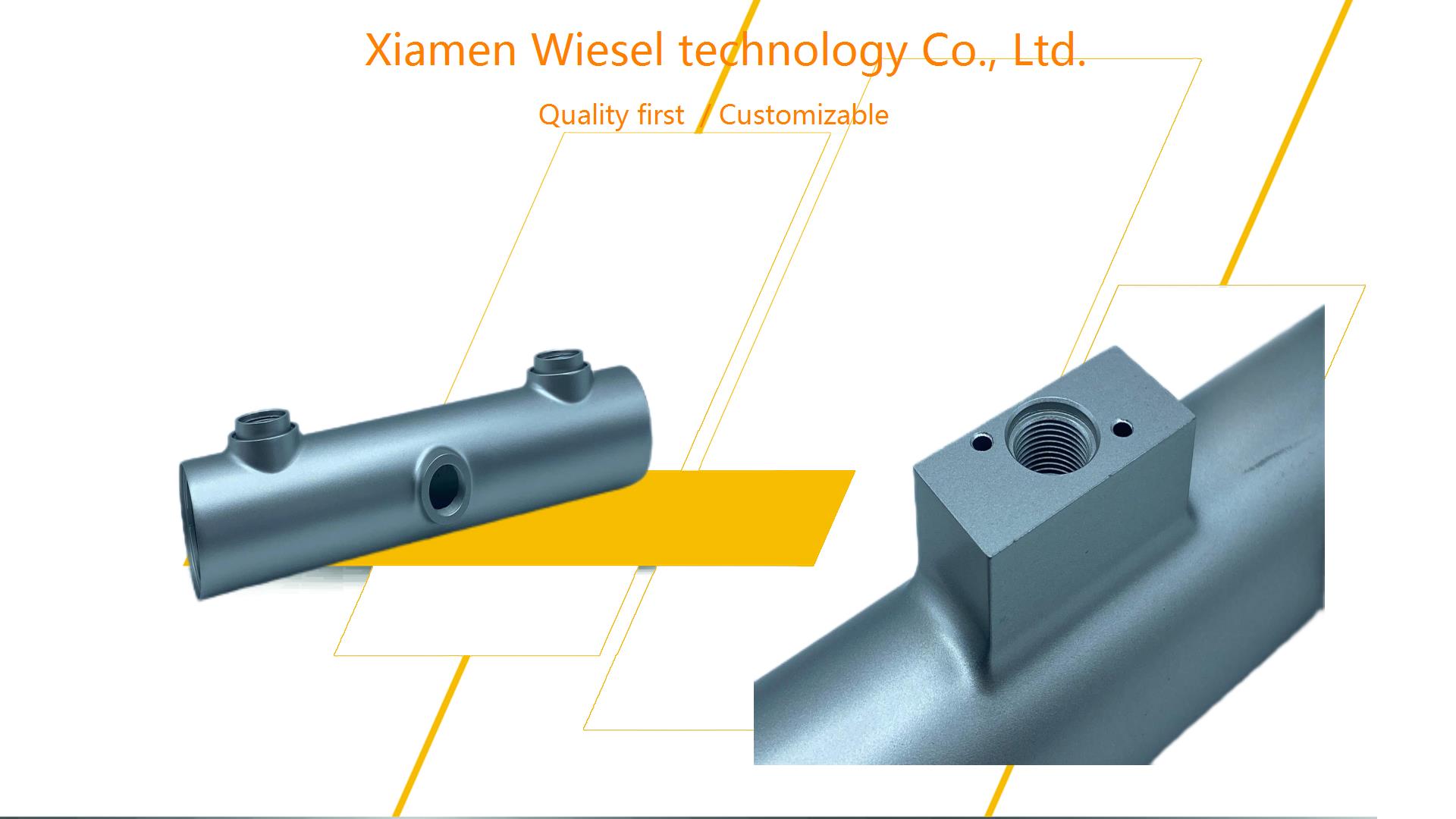

Wiesel, a leader in plastic mold manufacturing, also specializes in creating high-quality zinc alloy molds for precision manufacturing across various industries. Zinc alloy molds are highly sought after for their durability, strength, and ability to produce intricate designs with remarkable accuracy. The use of zinc alloys in mold-making provides several benefits that enhance the efficiency and quality of the final product.

One of the key advantages of using zinc alloy molds is their dimensional stability. Zinc alloys allow for the production of highly detailed and intricate parts due to their low melting point, which ensures precise shaping and uniformity. This makes them ideal for applications requiring tight tolerances and highly detailed surfaces, such as in automotive components, electronics, and consumer goods.

Additionally, zinc alloy molds offer excellent corrosion resistance and wear durability, ensuring a long service life even under intense production conditions. This not only extends the life of the mold but also reduces maintenance costs and downtime for repairs or replacements. The natural lubricity of zinc also minimizes wear on machinery, making it an excellent choice for high-volume production runs.

How Do Zinc Alloy Molds Compare to Other Mold Materials?

Strength and Durability

Compared to other mold materials like aluminum or plastic, zinc alloys offer superior strength and durability. Zinc alloy molds can withstand high levels of stress and maintain their integrity through repeated use in manufacturing environments. This makes them a more cost-effective option in the long run, as they can produce thousands of units without degrading. While aluminum molds are lighter, they often lack the strength needed for heavy-duty applications, making zinc alloys the better choice for precision manufacturing.

Versatility and Cost-Efficiency

Zinc alloy molds are also highly versatile, offering design flexibility for a wide range of industries. Compared to more expensive materials like steel, zinc offers a more affordable option while still delivering exceptional precision and durability. This makes zinc alloys a popular choice for manufacturers looking to balance cost with quality. Furthermore, zinc alloy molds are easier to produce than steel molds, which can involve more complex machining processes, reducing both production times and costs.

Peer Product Comparison: How Do Wiesel Zinc Alloy Molds Compare to Competitors?

When comparing Wiesel’s zinc alloy molds to those from competitors like Dynacast or Die-Tech, Wiesel stands out for its focus on customization and precision engineering.

Precision and Customization

While Dynacast is known for its large-scale zinc alloy production, Wiesel provides more tailored solutions with a focus on precision manufacturing for specific industry needs. Wiesel’s commitment to tight tolerances and intricate designs ensures that their zinc alloy molds deliver superior performance, especially for highly detailed components required in automotive, electronics, and consumer products.

Durability and Cost-Effectiveness

Compared to Die-Tech, Wiesel’s zinc alloy molds offer a better combination of durability and cost-efficiency. While Die-Tech provides competitive pricing, Wiesel’s molds are engineered for longer service life and higher production volumes, giving manufacturers better value for money over the lifespan of the mold.

Conclusion

Wiesel’s zinc alloy molds provide significant benefits for precision manufacturing, offering excellent durability, corrosion resistance, and dimensional stability. Compared to other materials like aluminum or steel, zinc alloys strike the perfect balance between strength and cost-efficiency. With superior customization and precision, Wiesel’s zinc alloy molds stand out against competitors such as Dynacast and Die-Tech, making them the ideal choice for industries that require high-quality, detailed components at an affordable price.