Why Are Metal CNC Solutions Crucial for High-Precision Tooling and Prototyping?

Metal CNC solutions play a critical role in achieving high-precision tooling and prototyping due to their ability to manufacture complex parts with tight tolerances and exceptional surface finishes. Industries such as automotive, aerospace, and electronics rely on CNC machining to create intricate components and prototypes that meet strict dimensional accuracy requirements. Wiesel, a leading plastic mold manufacturer, leverages its expertise in CNC machining to provide high-quality metal solutions that ensure precision, durability, and consistency in tooling and prototyping. By utilizing advanced CNC technology, Wiesel’s metal solutions enable manufacturers to produce parts with excellent repeatability and reduced lead times, making them ideal for both small-scale prototypes and full-scale production.

How Do Wiesel’s Metal CNC Solutions Enhance the Tooling and Prototyping Process?

Superior Accuracy and Surface Finish for Complex Designs

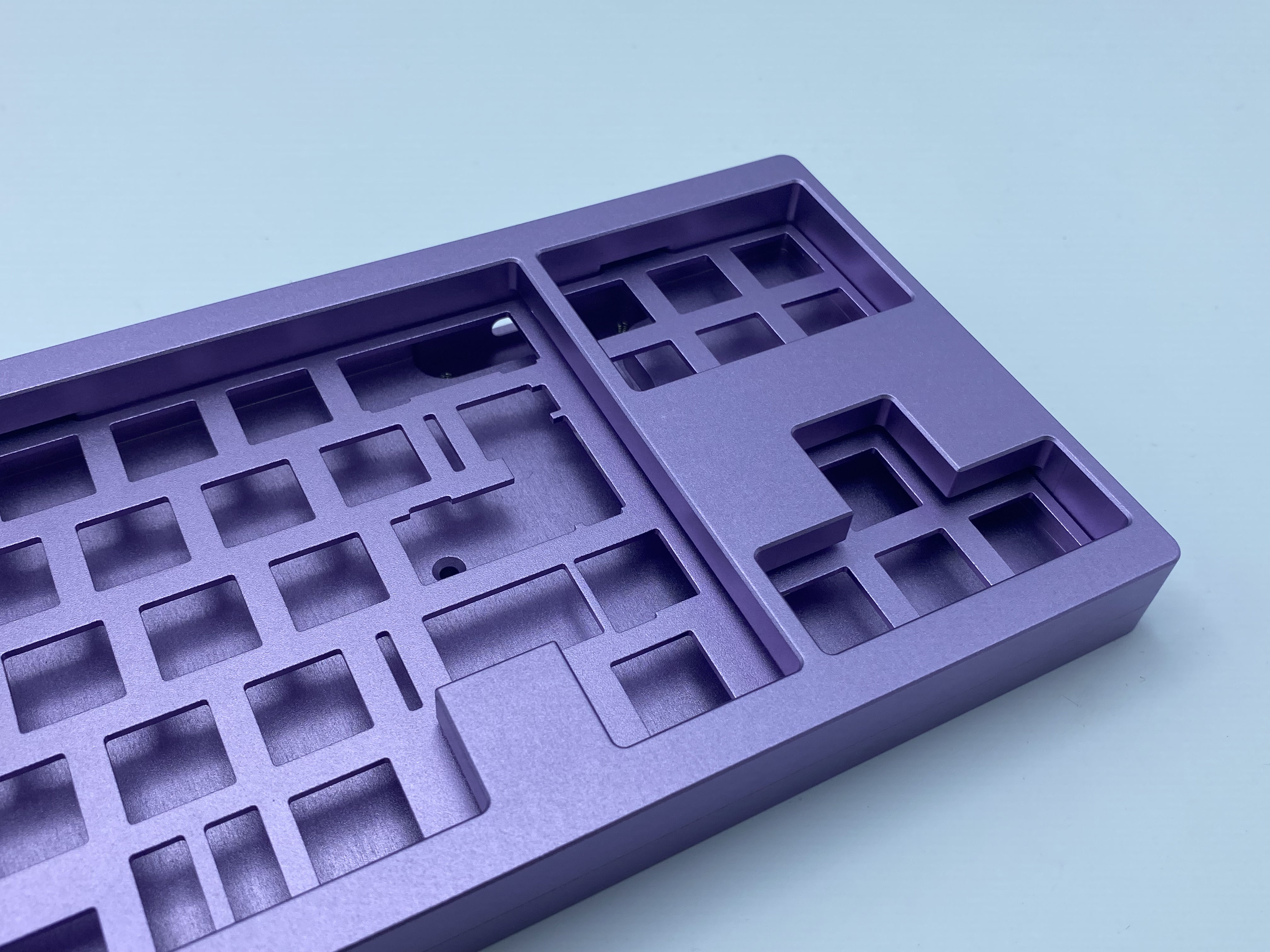

Wiesel’s metal CNC solutions are designed to achieve superior accuracy, even in the most complex designs. With state-of-the-art CNC machines and experienced operators, Wiesel can produce intricate geometries with micron-level precision, ensuring that every detail of the part is manufactured to exact specifications. This high level of precision is essential for tooling applications, where even the slightest deviation can affect the functionality and performance of the final product. The advanced machining capabilities of Wiesel’s CNC solutions also result in smooth surface finishes, minimizing the need for additional post-processing and polishing.

Versatile Material Options for Diverse Applications

Wiesel’s metal CNC solutions are compatible with a wide range of materials, including aluminum, stainless steel, titanium, and various alloys, making them suitable for diverse applications across multiple industries. This versatility allows manufacturers to select the most appropriate material for their specific tooling or prototyping needs, ensuring optimal performance, durability, and cost-efficiency. Whether for creating high-strength tools or lightweight prototypes, Wiesel’s CNC machining solutions offer the flexibility to meet varying material requirements while maintaining high quality and precision.

Final Thoughts on Metal CNC Solutions for High-Precision Tooling and Prototyping

In conclusion, metal CNC solutions are indispensable for achieving high-precision tooling and prototyping, providing superior accuracy, versatility, and efficiency in manufacturing complex parts. Wiesel’s expertise in CNC machining, combined with its commitment to quality, ensures that every component produced meets the highest standards of precision and performance. For manufacturers seeking reliable and high-quality metal CNC solutions, Wiesel offers the technology and experience needed to support both prototyping and production needs. Contact Wiesel today to learn more about our metal CNC solutions and how they can enhance your tooling and prototyping projects.