What Factors Should You Consider When Selecting CNC Milling Parts for Complex Designs?

Choosing the right CNC milling parts is crucial for achieving the desired accuracy, functionality, and aesthetics in complex designs. Factors such as material selection, dimensional tolerances, surface finish, and the complexity of the geometry all play a significant role in determining the effectiveness of the final product. Wiesel, a leading plastic mold manufacturer, offers a comprehensive range of CNC milling solutions that cater to the specific needs of complex designs. By understanding the key considerations for selecting CNC milling parts, designers and manufacturers can ensure optimal performance and quality for even the most intricate projects.

How Do CNC Milling Parts Enhance the Production of Complex Components?

Material Compatibility and Machinability

The material chosen for CNC milling has a direct impact on the manufacturability and performance of complex designs. Wiesel provides a wide selection of materials, including metals like aluminum, stainless steel, and titanium, as well as high-grade plastics such as ABS, PEEK, and polycarbonate. Each material offers unique properties that influence its machinability, strength, and surface finish. For complex components, it’s essential to select a material that can withstand the required machining processes while maintaining the desired mechanical properties. Wiesel’s expertise in material compatibility ensures that every CNC milled part meets the specific requirements of the project, whether it’s for prototyping or final production.

Precision Tolerances and Surface Finishes for High-Quality Results

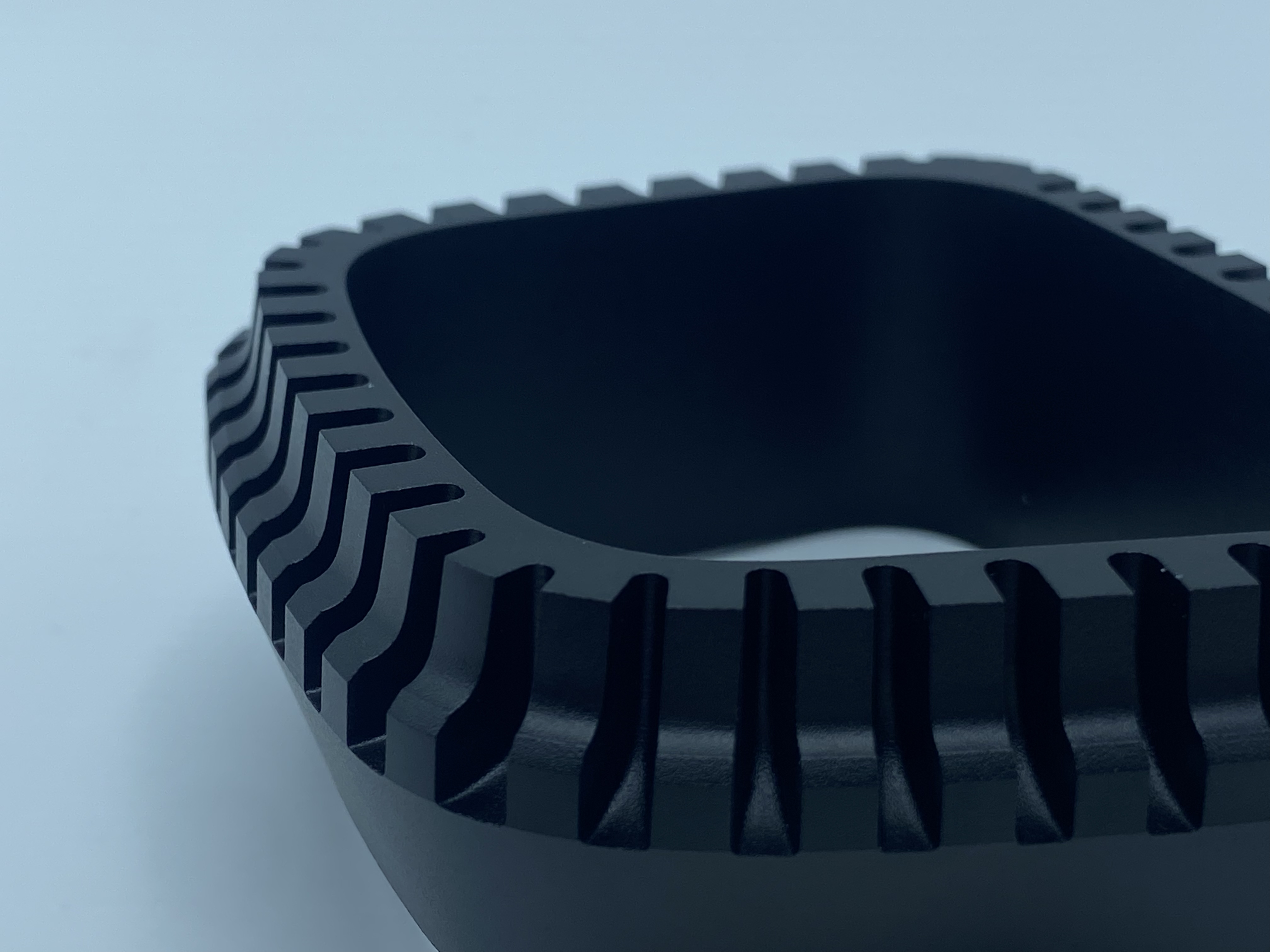

Precision tolerances and surface finishes are critical aspects of CNC milling, especially when creating complex designs with tight geometries. Wiesel’s advanced CNC milling machines are capable of achieving micron-level tolerances, ensuring that each part is manufactured to exact specifications. High-quality surface finishes, such as polished or matte textures, can be achieved depending on the project’s needs. This level of precision and attention to detail is essential for applications such as plastic molds, aerospace components, and medical devices, where accuracy and consistency are paramount.

Final Thoughts on Choosing the Right CNC Milling Parts for Complex Designs

In conclusion, selecting the right CNC milling parts for complex designs requires careful consideration of factors such as material compatibility, precision tolerances, and surface finishes. Wiesel’s extensive experience in CNC milling and plastic mold manufacturing enables the production of high-quality, intricate components that meet the specific requirements of any project. With a focus on precision and versatility, Wiesel’s CNC milling solutions ensure that complex designs are manufactured to the highest standards. Contact Wiesel today to learn more about our CNC milling capabilities and find the ideal solution for your complex design needs.