Ultrasonic welding is a welding process that uses high-frequency ultrasonic as a heat source and pressure source to obtain instantaneous high temperature and pressure on the surface of the workpiece, so as to soften, melt and fuse the workpiece materials.

The working principle of Ultrasonic welding is: during welding, the power source converts the electric energy into ultrasonic energy, and transmits the ultrasonic wave to the workpiece surface through the welding joint, so that the contact between the two workpieces is heated by friction, and dense fusion is carried out under a certain pressure to form a solid welding joint.

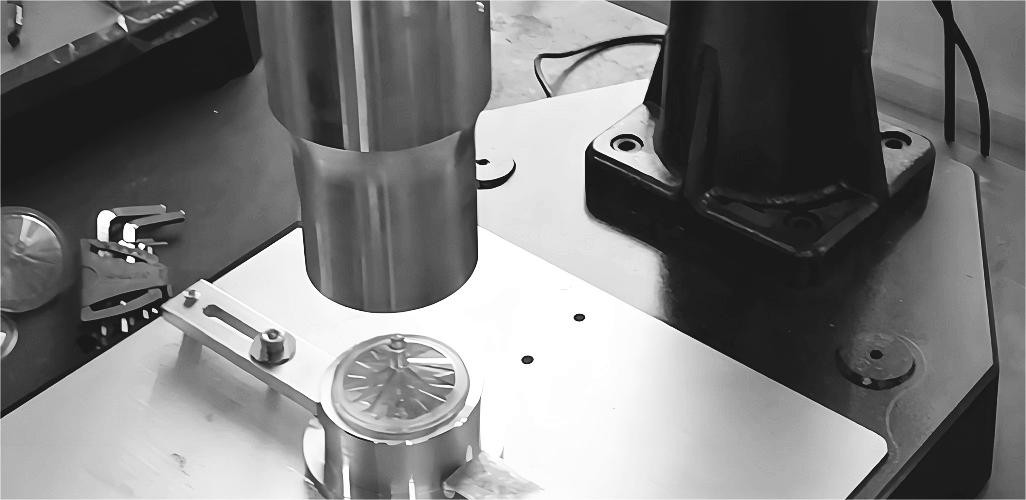

Ultrasonic welding equipment is usually composed of generator, transducer, welding joint, workpiece and control system. Among them, the generator is the core component that converts electrical energy into ultrasonic energy. The transducer converts the electrical energy of the generator into mechanical vibration, and the welding head transmits the mechanical vibration to the surface of the workpiece through contact for friction heating and pressure dense fusion. The entire process is automatically controlled by the control system.

Ultrasonic welding has the advantages of fast welding speed, simple operation, high welding joint strength, environmental friendliness, etc. It is widely used in many industries such as automobile, electronics, pharmacy, medical treatment, food, chemical industry, etc.

| Material | ABS | ABS+PC | PE | PP | PS | PMMA | NYLON | PC |

| ABS | Good | Good | / | / | / | / | / | Limited |

| ABS+PC | Good | Good | / | / | / | / | / | Limited |

| PE | / | / | Good | / | / | / | / | / |

| PP | / | / | / | Good | / | / | / | / |

| PS | / | / | / | / | Good | / | / | / |

| PMMA | / | / | / | / | / | Good | / | / |

| NYLON | / | / | / | / | / | / | Good | / |

| PC | Limited | Limited | / | / | / | Limited | / | Good |

Provide Comprehensive Product Technology Solutions