Metal Injection Molding (MIM) is an efficient and precise metal processing technology that combines the advantages of plastic injection molding and traditional powder metallurgy processes. it allows the production of complex shaped metal parts and achieves high density and detailed while achieving near net forming.

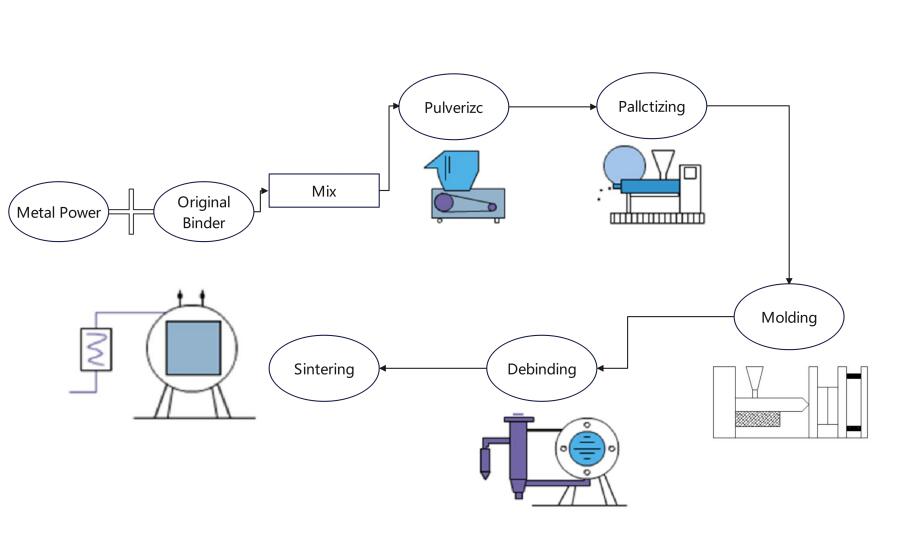

Main steps of metal injection molding: Mixed material ,Pulverizc material, Pallctizing, Molding, Debinding, Sintering,Treatment.

Provide Comprehensive Product Technology Solutions