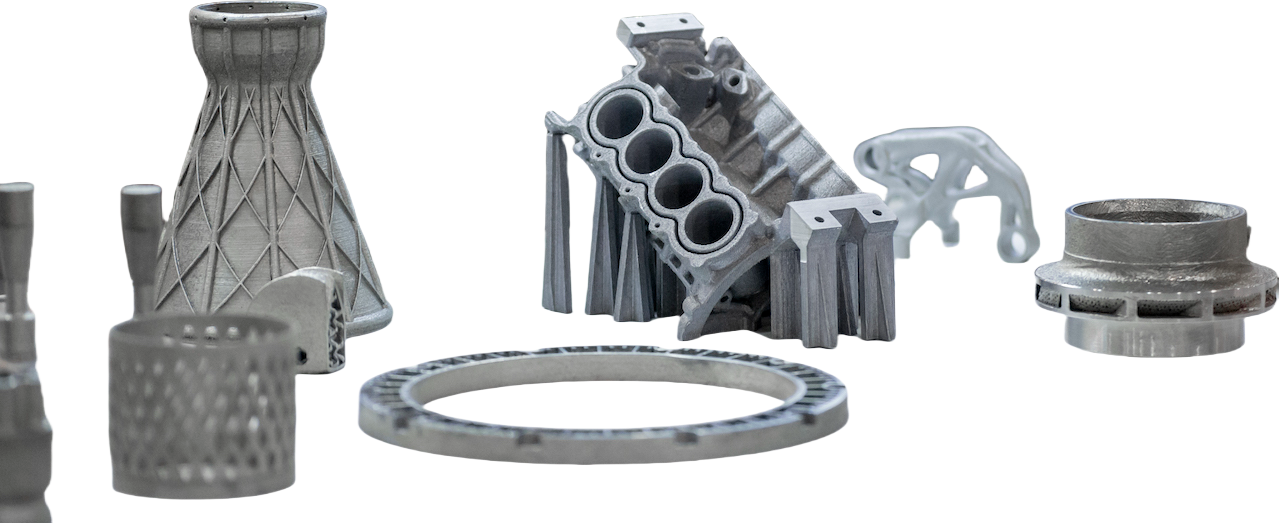

Metal 3D printing is a revolutionary technology that produces impossible-to-make parts directly from your CAD data. Advantages to this process include the ability to produce strong, complex geometries, internal lattice structures, conformal cooling channels and other features that cannot be made with traditional machining. Parts can be made quickly with a minimum of material waste making them ideal for next-generation engineering in aerospace, medical, automotive and other industries

There are many benefits for 3D printing, especially if you know how to optimize your product design to take advantage of them.

| Material | Type | Physical Property | Property OF Product | |||||

| Rosolution | Size | Mobility | Density | Density | Tensile (MPa) | Yield (MPa) | ||

| Stainless Steel | 316L | 15-53μm | Sphere | 40s | 3.9g/cm3 | >99% | >560 | >480 |

| Mold Steel | MS1 | 15-53μm | Sphere | 40s | 4.3/cm3 | >99% | >1090 | >1000 |

| Titanium | TC4 | 15-53μm | Sphere | 45s | 2.5g/cm3 | >99% | >600 | >540 |

| Aluminum | AlSi10Mg | 15-53μm | Sphere | 150s | 1.45g/cm3 | >99% | >330 | >245 |

| Nickel Base Steel | GH4169 | 15-53μm | Sphere | 45s | 4.4g/cm3 | >99% | >980 | >700 |

Only few hours to finish the parts, the product development cycle can be shorted by more than 60%

No need any manufacturing, Can directly print rapid prototype ,greatly reducing product development cost

Verify design, solve various fatal defects of new products, and avoid the high risk of mold opening and mold modification

Sample exhibition, quickly seize the market opportunity,instantly obtain a large number of order and objective cash

Provide Comprehensive Product Technology Solutions

Need custom Metal 3D Printing Service? Please contact with us