In today’s competitive manufacturing environment, the ability to rapidly develop and refine prototypes is crucial to delivering high-quality products effi

LEARN MORE →

What Factors Should You Consider When Selecting CNC Milling Parts for Complex Designs?Choosing the right CNC milling parts is crucial for achieving the desired

LEARN MORE →

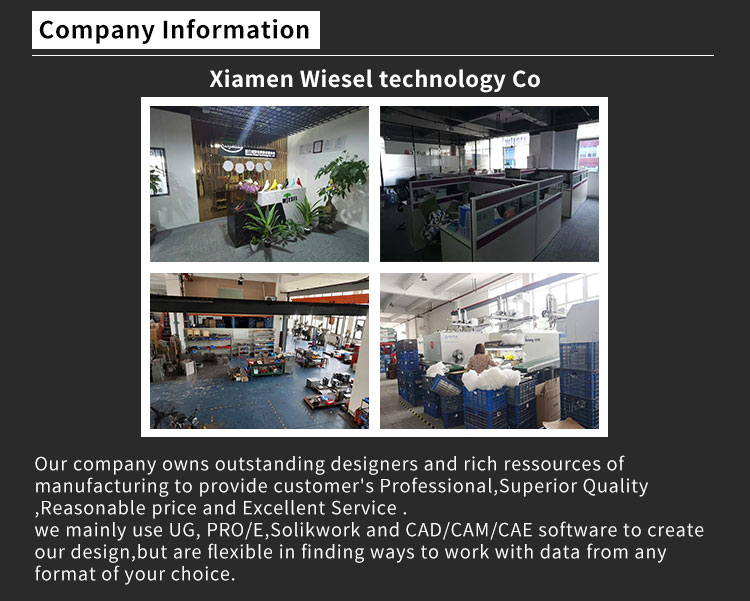

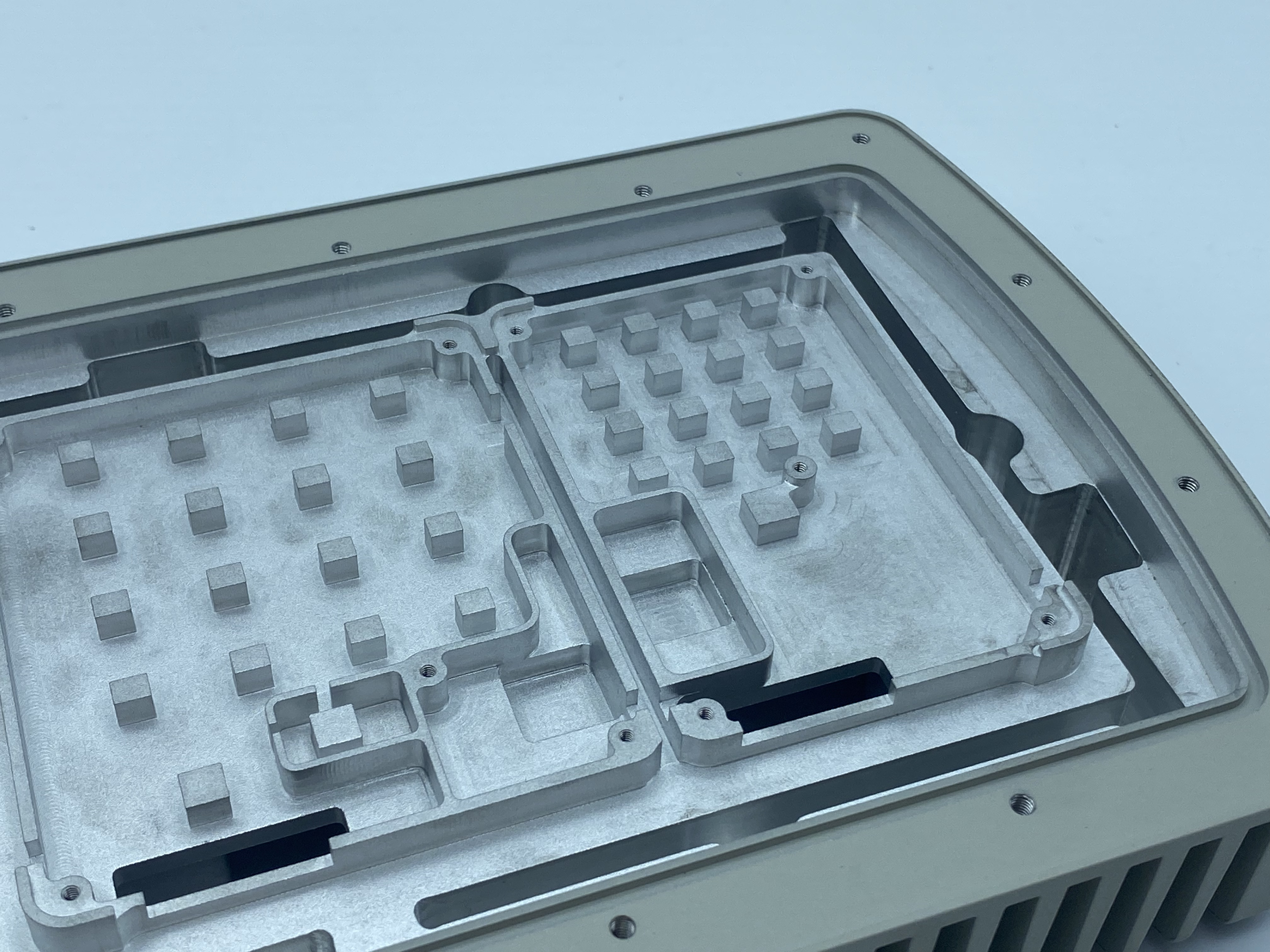

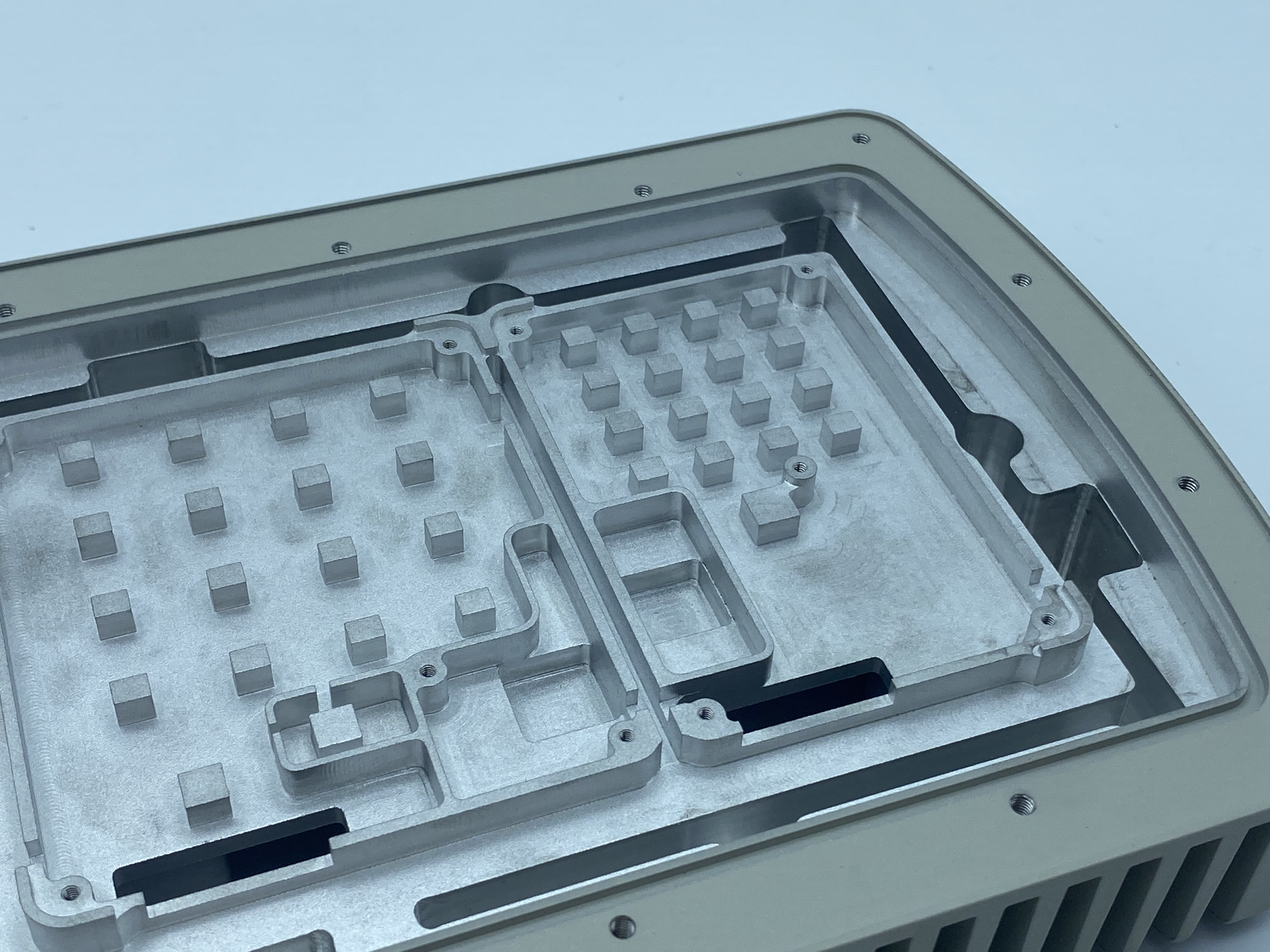

Metal CNC solutions play a critical role in achieving high-precision tooling and prototyping due to their ability to manufacture complex parts with tight tolerances and exceptional surface finishes. Industries such as automotive, aerospace, and electronics rely on CNC machining to create intricate components and prototypes that meet strict dimensional accuracy requirements. Wiesel, a leading plastic mold manufacturer, leverages its expertise in CNC machining to provide high-quality metal solutions that ensure precision, durability, and consistency in tooling and prototyping. By utilizing advanced CNC technology, Wiesel’s metal solutions enable manufacturers to produce parts with excellent repeatability and reduced lead times, making them ideal for both small-scale prototypes and full-scale production.

LEARN MORE →

Vacuum casting is a versatile and cost-effective manufacturing technique ideal for low-volume production and rapid prototyping of high-quality parts. Wiesel, a leading plastic mold manufacturer, offers advanced vacuum casting services that enable businesses to create precise prototypes and short-run production parts with exceptional detail and finish. The process is particularly useful for producing parts with complex geometries and smooth surfaces, making it an excellent choice for industries such as automotive, consumer electronics, and medical devices. In this article, we explore the benefits of vacuum casting and why it is an ideal solution for low-volume and rapid prototyping projects.

LEARN MORE →

Zinc alloy molds are widely used in the production of high-strength metal components that require exceptional durability, precision, and reliability. Wiesel, a leading plastic mold manufacturer, also specializes in creating high-quality zinc alloy molds that offer superior performance and longevity. With their excellent mechanical properties and ability to produce complex shapes with tight tolerances, zinc alloy molds are an ideal choice for manufacturing a variety of metal parts used in industries such as automotive, electronics, and consumer goods. In this article, we discuss the advantages of using zinc alloy molds and how they contribute to the production of long-lasting metal components.

LEARN MORE →

Wiesel, a trusted plastic mold manufacturer, understands the importance of selecting the right die casting machine for producing high-quality custom parts. Die casting machines are essential for creating complex components with precision and durability, especially in industries such as automotive, electronics, and industrial equipment. The right machine ensures consistency in mass production, tight tolerances, and excellent surface finishes. Wiesel’s die casting solutions are tailored to meet the specific requirements of custom parts, offering flexibility, accuracy, and efficiency to ensure that every product meets exacting standards.

LEARN MORE →

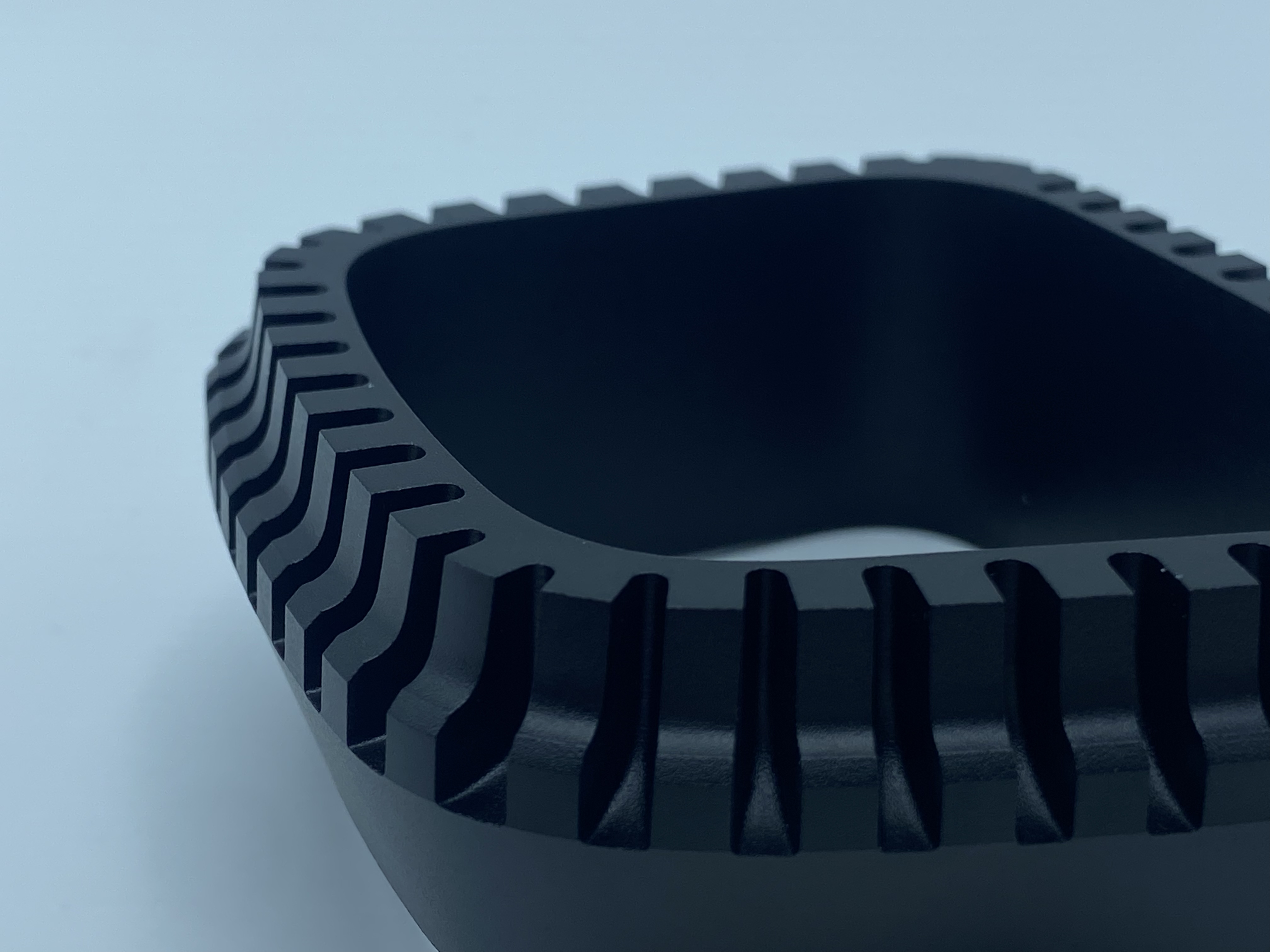

Wiesel, a leading plastic mold manufacturer, utilizes CNC turning as a critical process for producing high-precision components in a variety of industries. CNC turning involves the use of computer-controlled machines to rotate a workpiece while cutting tools are applied to shape it into the desired form. This method is particularly effective for creating cylindrical parts with exceptional accuracy, making it ideal for industries requiring tight tolerances and complex geometries. Wiesel’s CNC turning process ensures the production of high-quality plastic mold components, delivering precision, consistency, and efficiency for large-scale manufacturing projects.

LEARN MORE →

Wiesel, a prominent plastic mold manufacturer, extends its expertise into sheet metal fabrication to produce high-durability parts for various custom applications. Sheet metal fabrication is widely recognized for its ability to create strong, lightweight, and precise components, making it ideal for industries requiring robust yet versatile parts.

LEARN MORE →

Wiesel, a leader in plastic mold manufacturing, also specializes in creating high-quality zinc alloy molds for precision manufacturing across various industries. Zinc alloy molds are highly sought after for their durability, strength, and ability to produce intricate designs with remarkable accuracy. The use of zinc alloys in mold-making provides several benefits that enhance the efficiency and quality of the final product.

LEARN MORE →

Wiesel, a leading plastic mold manufacturer, is also proficient in various metal fabrication techniques, including stamping molds and die casting. While both processes are widely used in metal fabrication, they differ significantly in terms of methodology, materials, and applications.

Stamping molds involve the use of dies and presses to shape metal sheets into specific forms through processes such as cutting, bending, and pressing. This method is ideal for high-speed, high-volume production of relatively simple parts, making it a cost-effective option for industries like automotive and electronics.

LEARN MORE →

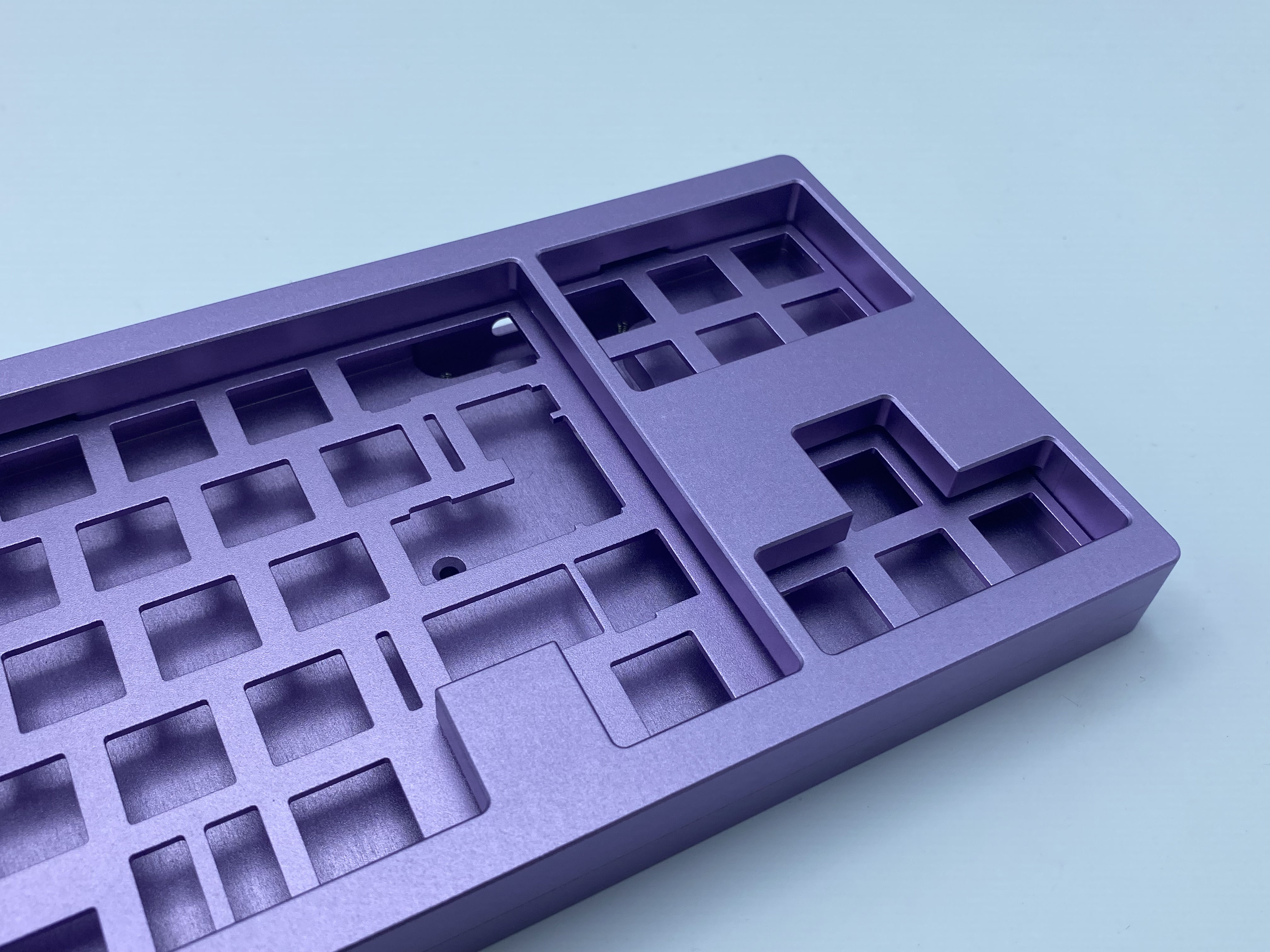

Wiesel, a leading plastic mold manufacturer, specializes in providing high-quality plastic CNC machines that are essential for producing custom parts with precision and efficiency. CNC (Computer Numerical Control) technology allows manufacturers to automate the production process, ensuring consistent and accurate results, particularly when dealing with complex designs or intricate details. Plastic CNC machines are widely used in industries such as automotive, consumer electronics, and medical devices, where custom parts are often required in small to medium batch sizes.

LEARN MORE →